National free service hotline:400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

National free service hotline:400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

Vertical check valve

Location:Home > Vertical check valve

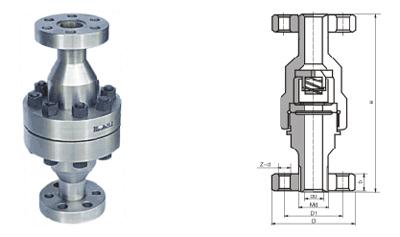

H42Y, H42W-type vertical lift check valve

Vertical check valve: due to the pressure in the inlet side of the pipeline role, and overcome the spring resistance to open or close the valve. When the inlet side of the media pressure is lower than the export side, the spring will push the valve seat valve seat valve closed, to prevent the media backflow, it is only from the role back. Vertical check valve is widely used in chemical industry, liquefied petroleum gas, fluid and other industries. Check valve by structure, can be divided into lift check valve, swing check valve and butterfly check valve three.

Vertical check valve is to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back valve, also known as check valve, check valve, counter-current valve, and back pressure valve. Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reverse, and the container media release. The check valve may also be used on a line in which the supply pressure of the auxiliary system may be increased beyond the system pressure. Check valve can be divided into swing check valve (according to the center of gravity rotation) and the lift check valve (along the axis of movement).

The purpose of this type of valve is to allow the medium to flow in only one direction and to block the direction

Vertical check valve structure diagram flow. Usually the valve is automatically working, in a direction of fluid pressure, the valve flap open; the reverse flow of fluid by the fluid pressure and the valve flap valve self-acting on the seat, which cut off the flow.

One internal thread check valve, butterfly check valve belongs to this type of valve, which includes swing-type check valve and lift check valve. Swing check valve has a hinge mechanism, as well as a door like the valve flap free to lean against the inclined seat surface. In order to ensure that the valve flap to reach the seat surface each time the appropriate position, the valve flap design in the hinge so that the valve flap has enough space to open space, and the valve real, full contact with the valve seat. The valve flap can be made entirely of metal, or it can be covered with leather, rubber, or a synthetic cover, depending on the performance requirements. Swing check valve in the fully open condition, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small. Lift check valve valve seat located in the valve seat sealing surface. The valve in addition to the valve can be free to lift, the rest of the same as the cut-off valve, the fluid pressure from the valve seat sealing surface lift up, the media return valve leading to the valve seat down and cut off the flow. Depending on the conditions of use, the valve flap may be of the all-metal construction, or may be in the form of a rubber pad or rubber ring mounted on the valve disc holder. Like the cut-off valve, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve swing larger than the swing check valve, and the flow of swing check valve is limited Very little.

Mobile site

App