National free service hotline:400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

National free service hotline:400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

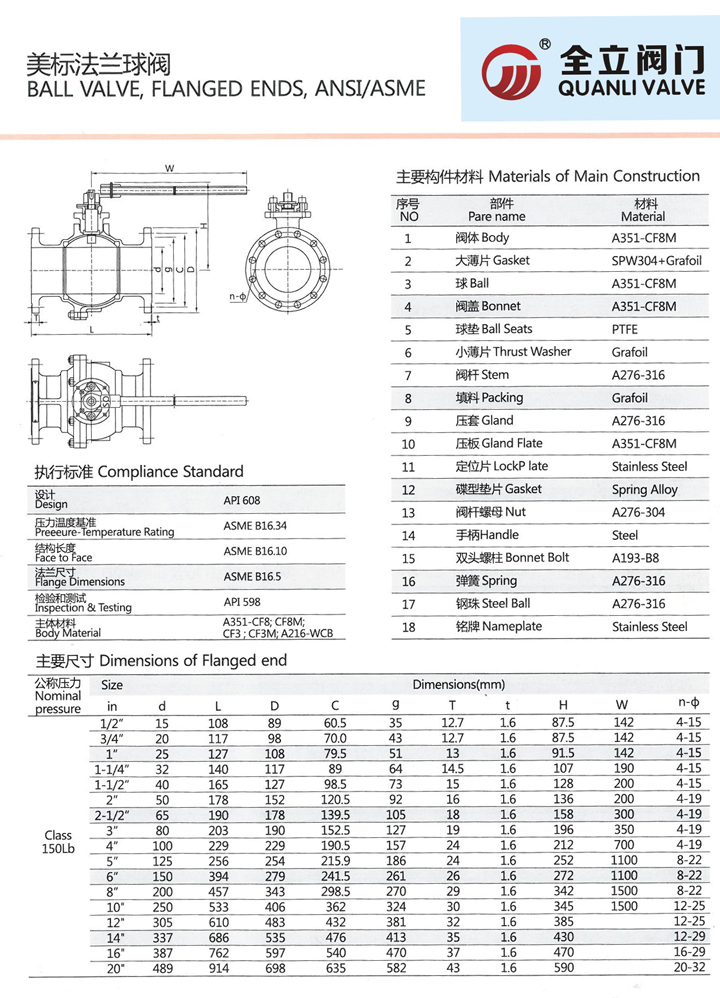

American standard ball valve

Location:Home > American standard ball valve

American standard stainless steel ball valve Q41F

Ball valve (ball valve in the field of marine and marine areas should be cut-off valve), the standard GB / T21465-2008 "Valve terminology" is defined as: opening and closing pieces (ball) Driven by the stem and rotary motion around the ball valve axis . Can also be used for fluid regulation and control, including hard-sealed V-type ball valve V-core ball and hardmetal surfacing between the metal valve seat has a strong shear, especially for fiber, tiny solid particles And the like. The multi-way ball valve in the pipeline can not only flexibly control the confluence of the medium, shunt, and the direction of the switch, but can also close any channel leaving the other two channels connected. This type of valve in the pipeline should generally be installed horizontally. Ball Valve Category: Pneumatic ball valve, electric ball valve, manual ball valve.

One; wear; seal the ball valve is hard alloy steel spray welding,

Three-piece ball valve is alloy steel welding, so hard-sealed ball valve in the switch will not produce too much wear and tear. (Its hardness coefficient is 65-70):

Second, good sealing performance; as a result of hard sealed ball valve sealing is the use of artificial grinding, until the valve core and the ring can be used in full compliance. So his sealing performance is reliable.

Three; switch light; as a result of hard sealing ball valve seal at the bottom of the spring and the spool to hold tightly together, so the outside force exceeds the spring preload when the switch is very light.

4; long service life: has been widely used in petroleum, chemical, power generation, paper, atomic energy, aviation, rockets and other departments, and people's daily lives.

Pneumatic ball valve is compact, reliable sealing, simple structure, easy maintenance, sealing surface and spherical surface are often in the closed state, not easily eroded by the medium, easy to operate and maintain. Suitable for water, solvent, acid and natural gas and other general working medium. In the cut-off or connected to the medium in the pipeline, can also be used for fluid adjustment and control.

Pneumatic ball valve and other types of valves, compared with the angular output torque, open quickly, smooth and reliable, wide range of applications, and so the following advantages.

1, thrust bearings to reduce stem friction torque, long-term operation of the valve stem can be smooth and flexible.

2, anti-static function: in the sphere, stem, set the spring between the valve body, the process can produce static electricity export.

3, PTFE and other materials with good self-lubricating, and the ball friction loss is small, so the long life of pneumatic valve.

4, the fluid resistance is small: Pneumatic ball valve is the smallest class of all fluid resistance in a class, even the reduced diameter pneumatic valve, the fluid resistance is quite small.

5, stem seal and reliable: As the stem only for the imitation of rotation without lifting movements, the stem of the packing seal is not easy to damage, and the sealing capacity increases with the media pressure increases.

6, the valve seat sealing performance: PTFE and other elastic materials made of seals, the structure is easy to seal, and pneumatic valve valve sealing capacity increases with the media pressure increases.

DN | (kg)Weight | |||||||||

mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | |

15 | 1/2 | 108 | 89 | 60.5 | 35 | 11.5 | 4-15 | 59 | 130 | 2.2 |

20 | 3/4 | 117 | 98 | 70 | 43 | 11.5 | 4-15 | 63 | 130 | 3.0 |

25 | 1 | 127 | 108 | 79.5 | 51 | 12 | 4-15 | 75 | 160 | 4.5 |

32 | 11/4 | 140 | 117 | 89 | 64 | 13 | 4-15 | 75 | 160 | 5.5 |

40 | 11/2 | 165 | 127 | 98.5 | 73 | 15 | 4-15 | 95 | 230 | 7.0 |

50 | 2 | 178 | 152 | 120.5 | 92 | 16 | 4-19 | 107 | 230 | 9.5 |

65 | 11/2 | 190 | 178 | 139.7 | 105 | 18 | 4-19 | 142 | 400 | 15 |

80 | 3 | 203 | 190 | 152.5 | 127 | 19 | 4-19 | 152 | 400 | 19 |

100 | 4 | 229 | 229 | 190.5 | 157 | 24 | 8-19 | 178 | 700 | 33 |

125 | 5 | 256 | 254 | 215.9 | 186 | 24 | 8-22 | 252 | 1100 | 58 |

150 | 6 | 394 | 279 | 241.5 | 261 | 26 | 8-22 | 272 | 1100 | 93 |

200 | 8 | 457 | 343 | 298.5 | 270 | 29 | 8-22 | 342 | 1500 | 160 |

250 | 10 | 533 | 406 | 362 | 324 | 31 | 12-25 | 345 | 1500 | 200 |

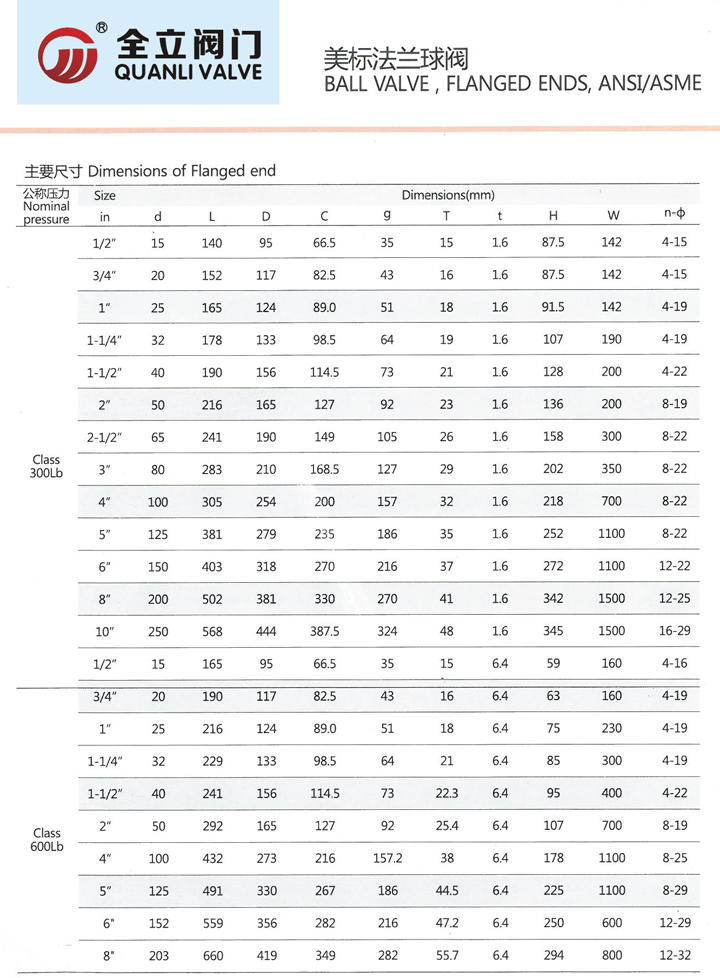

American standard ball valve 300Lb 300LbP 300LbR | ||||||||||

15 | 1/2 | 140 | 95 | 66.5 | 35 | 14.3 | 4-15 | 59 | 130 | 2.5 |

20 | 3/4 | 152 | 117 | 82.5 | 43 | 15.9 | 4-19 | 63 | 130 | 3.5 |

25 | 1 | 165 | 124 | 89 | 51 | 17.5 | 4-19 | 75 | 160 | 5.5 |

32 | 11/4 | 178 | 133 | 98.5 | 64 | 19.1 | 4-19 | 75 | 160 | 4.0 |

40 | 11/2 | 190 | 156 | 114.5 | 73 | 20.7 | 4-22 | 95 | 230 | 10.0 |

50 | 2 | 216 | 165 | 127 | 92 | 22 | 8-19 | 107 | 230 | 14.5 |

65 | 11/2 | 241 | 190 | 149 | 105 | 25 | 8-22 | 142 | 400 | 23.5 |

80 | 3 | 283 | 210 | 168 | 170 | 29 | 8-22 | 152 | 400 | 30 |

100 | 4 | 305 | 254 | 200 | 157 | 32 | 8-22 | 178 | 700 | 55 |

125 | 5 | 381 | 279 | 235 | 186 | 35 | 8-22 | 252 | 1100 | 81 |

150 | 6 | 403 | 318 | 270 | 216 | 37 | 12-22 | 272 | 1100 | 118 |

200 | 8 | 502 | 381 | 330 | 270 | 41 | 12-25 | 342 | 1500 | 200 |

250 | 10 | 568 | 444 | 387.5 | 324 | 48 | 16-29 | 345 | 1500 | 250 |

American standard ball valve 600Lb 600LbP 600LbR | ||||||||||

15 | 1/2 | 165 | 95 | 66.5 | 35 | 14.3 | 4-16 | 59 | 160 | 7.5 |

20 | 3/4 | 190 | 117 | 82.5 | 43 | 15.9 | 4-19 | 63 | 160 | 10.5 |

25 | 1 | 216 | 124 | 89 | 51 | 17.5 | 4-19 | 75 | 230 | 14.5 |

40 | 11/2 | 241 | 156 | 114.5 | 73 | 22.3 | 4-22 | 95 | 400 | 18.5 |

50 | 2 | 292 | 165 | 127 | 92 | 25.4 | 8-19 | 107 | 700 | 25 |

100 | 4 | 432 | 273 | 216 | 157.2 | 38 | 8-25 | 178 | 1100 | 76 |

125 | 5 | 508 | 330 | 267 | 186 | 44.5 | 8-29 | 25.5 | 1100 | 102 |

Mobile site

App